|

|

|

Charge / Recharge Closed Loop Solar Hot Water System |

||

Iwalani's Voyage Around the World Weekly logs of Iwalani's three year circumnavigation written by Philip Shelton, Amy P. Wood and Stewart the Cat.  The "World Voyagers" Book A true story of the three year circumnavigation by Philip Shelton, Amy Wood and Stewart the cat. From designing and building a 42 foot wooden cutter "Iwalani" to sailing around the world— this is not a watered down, sugar coated tale, but a "no holds barred" account of just what it's like to live a "dream." |

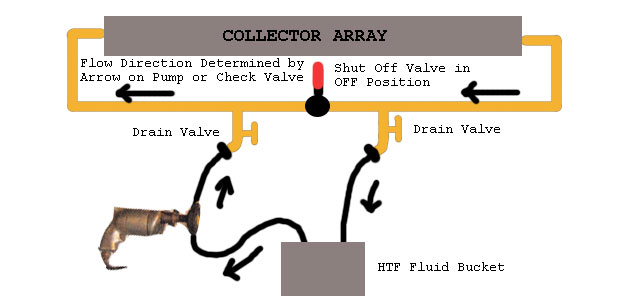

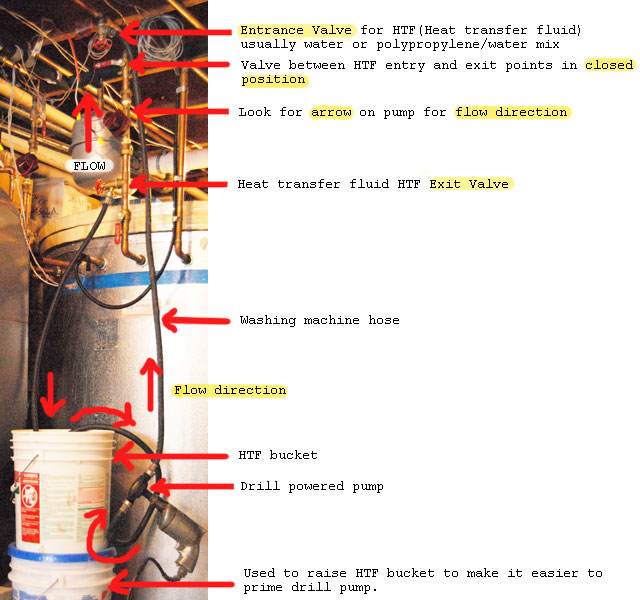

How to Charge or Recharge Closed Loop Solar Hot Water System 1 ) Determine the direction of flow by looking for the arrow on the pump or a check valve. 2 ) Locate two drain valves (they look like garden hose faucets). 3 ) Locate the shut off valve between drain valves and close the shut off valve. 4 ) Locate closed loop pressure gauge. 5 ) Attach washing machine hose to closed loop exit and place free end in the bucket. 6 ) Fill bucket at least half full of heat transfer fluid HTF (water or polypropylene glycol/water mix). Have more HTF ready to add to bucket. It takes about 1 gallon to fill 100 feet of 1/2 inch pipe and 2.3 gallons to fill 100 feet of 3/4 inch pipe. Polypropylene glycol is non-toxic, unlike polyethylene glycol (car antifreeze), which can kill cats and dogs if they drink it. 7 ) Attach washing machine hose to both sides of drill powered pump (glycol transfer pump) and prime drill pump by running it before connecting to entrance drain valve. Be sure it's pumping correctly (in the right direction). 8 ) Connect drill pump hose to closed loop entrance valve. 9 ) Check to make sure shut off valve between loop entrance and exit valves is in the closed position. 10 ) Start drill pump and open loop entrance valve fully. 11 ) Open loop exit valve fully. 12) Make sure drill pickup hose remains below HTF level in bucket. As HTF level lowers, add more. 13) When loop exit hose stops blowing air bubbles, close loop exit valve while still running drill pump. 14) Watch pressure gauge in closed loop line. When pressure reaches 30psi, shut loop entrance valve while still running drill pump. 15) Shut off drill pump. 16) Watch for pressure drop. Pressure drop could indicate leak in closed loop or air still purging through automatic air vents. 17) If pressure drops and then remains the same after 24 hours, repeat procedure to return pressure to 30psi.

|

Mouse Over the Image Above for a LARGER View of the SkyCam Picture

Updated Every 15 Minutes |