|

Solar Collector System

1) 3 - Silicon Solar 20 evacuated tube collectors on a 67 degree tilt.

2) 1 -328 gallon STSS storage tank. The water in this tank does NOT mix with the solar collector transfer fluid or the domestic hot water. Tank sides and bottom covered with 2 inch Thermax. Top is covered with 6 inch Thermax.

3) Collector heat exchanger is a 60ft ¾”copper coil in the bottom of the storage tank.

4) Domestic hot water goes through a 120 ft ¾” copper coil in the storage tank, above the solar collector coil.

5) Collector transfer fluid is 3.8 gallons (100ft 3/4inch pipe=2.29 gal) "Sierra" brand 50/50 water/polypropylene glycol mix.

6) All piping for the solar collectors is ¾” copper pipe. Collector total run (including heat exchanger) is 170 feet.

7) Heliotrope check valves in collector loop.

8) All collector piping is insulated with Armacell closed cell black foam.

9) Collector pump is a 10w Ivan Labs el-sid - PV powered 0-21volts DC.

10) 3-10w Kyocera PV panels power the collector pump. Faceted to face east, south and west.

11) Collector differential controller is an IMC Eagle D2 PV powered.

12) DLJ flow meter with dry reed switch for digitally counting the gallons of domestic hot water used.

13) Our own design flow detector for BTU calculations.

12) Data logging and web posting by WEL data logger.

Radiant Heat System

1) Radiant heat exchanger is 180 ft ¾” copper coil in the storage tank.

2) Radiant heat transfer fluid is a 50/50 water/polypropylene glycol mix.

3) Heliotrope check valve in radiant loop.

4) Radiant heat loop is 180 ft ½” hot water Pex tubing.

5) Crusher dust between Pex tubes to support paving bricks.

6) 2 inch thick paving bricks over crusher dust.

7) Radiant floor is insulated with 6 in Thermax foam under the Pex and along the frost wall with an R value of 40.

8) Radiant pump is and Ivan Labs 10w 12v el-sid.

9) 12 volt DC deep cycle battery for radiant pump.

10) 40w Kyocera PV panel for charging deep cycle battery.

11) TPS-535 solar charge/regulator for deep cycle battery.

12) Radiant heat space is 180 sq ft attached green house with 90 sq ft double glazed windows.

12) Radiant heat controller is a K190 kit relay board. Low tank temp shutoff at 70 degrees .

WEL Information

One-wire bus sensor leads CAN NOT be longer than 2ft. Use star configuration instead (several long leads from the WEL with sensors off of them.)

Do Not use hardware store wire taps. Use commercial grade, dielectric grease filled taps.

Do Not use Cat3 cable for the one-wire bus. Use Cat5 or the wire supplied by WEL.

Click HERE for WEL expressions, constants and formulas used for our solar hot water system.

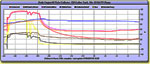

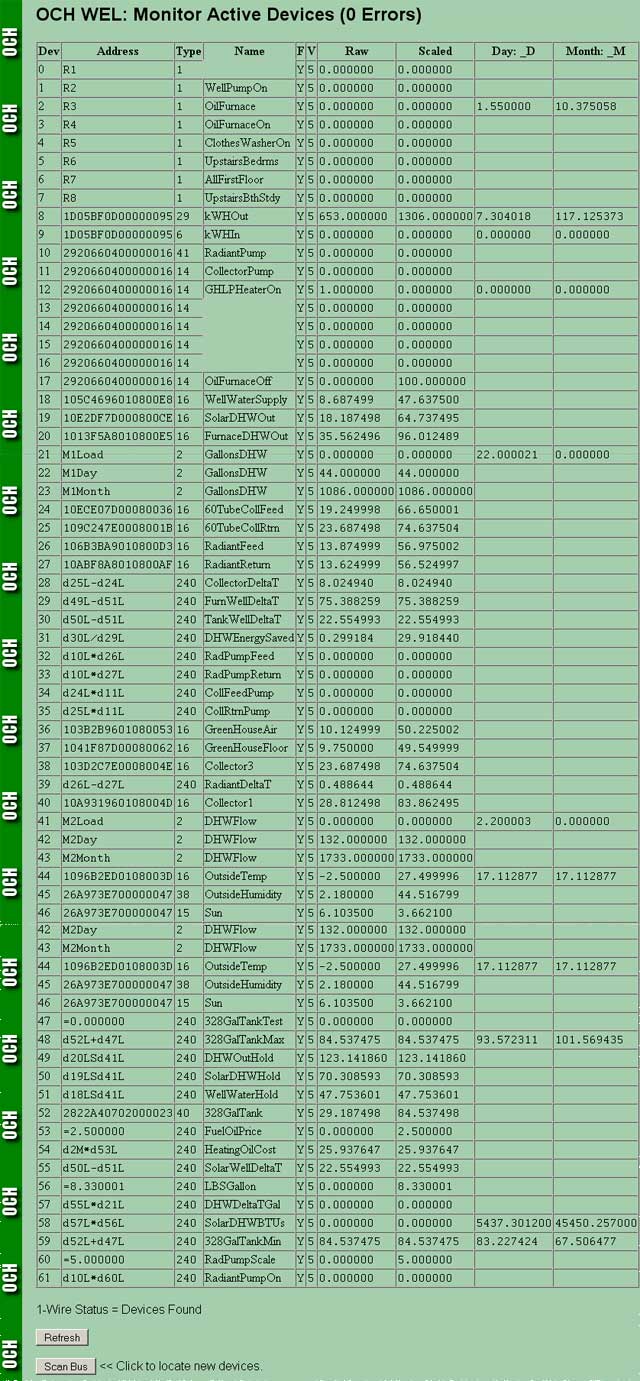

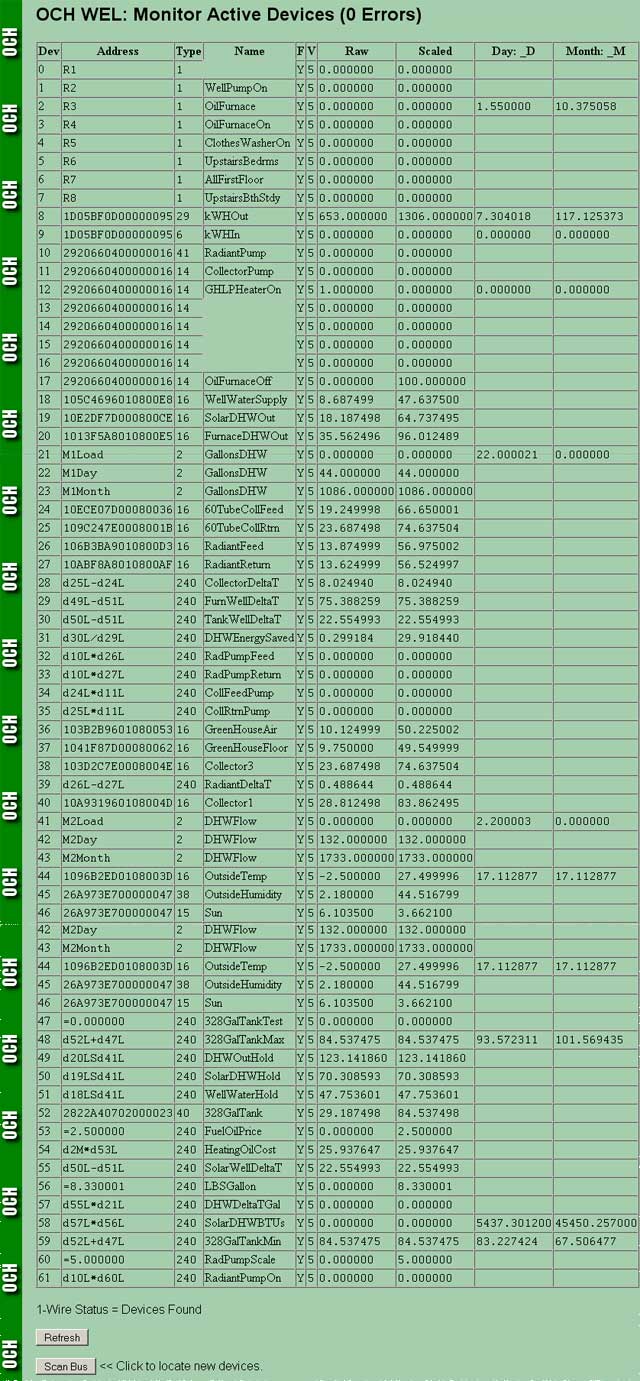

Below is a screen shot of the WEL Live Data Table. The left column shows device ID's. Where there is no device ID, there is an operator ( + - * / { }S) tied to the virtual device (the name you give for the result of the equation), which identifies the devices involved. The L after the device number means Live data, as opposed to Day or Month accumulations. You can also create a constant that would be applied to a result. For example device 53 defines a constant of 2.50, which is the price of 1 gallon of fuel oil. Device 56 is 8.33, which converts gallons to pounds for BTU calculations. Constants and expressions can be combined, with a limit of up to 128 devices. Click HERE for more BTU calculations.

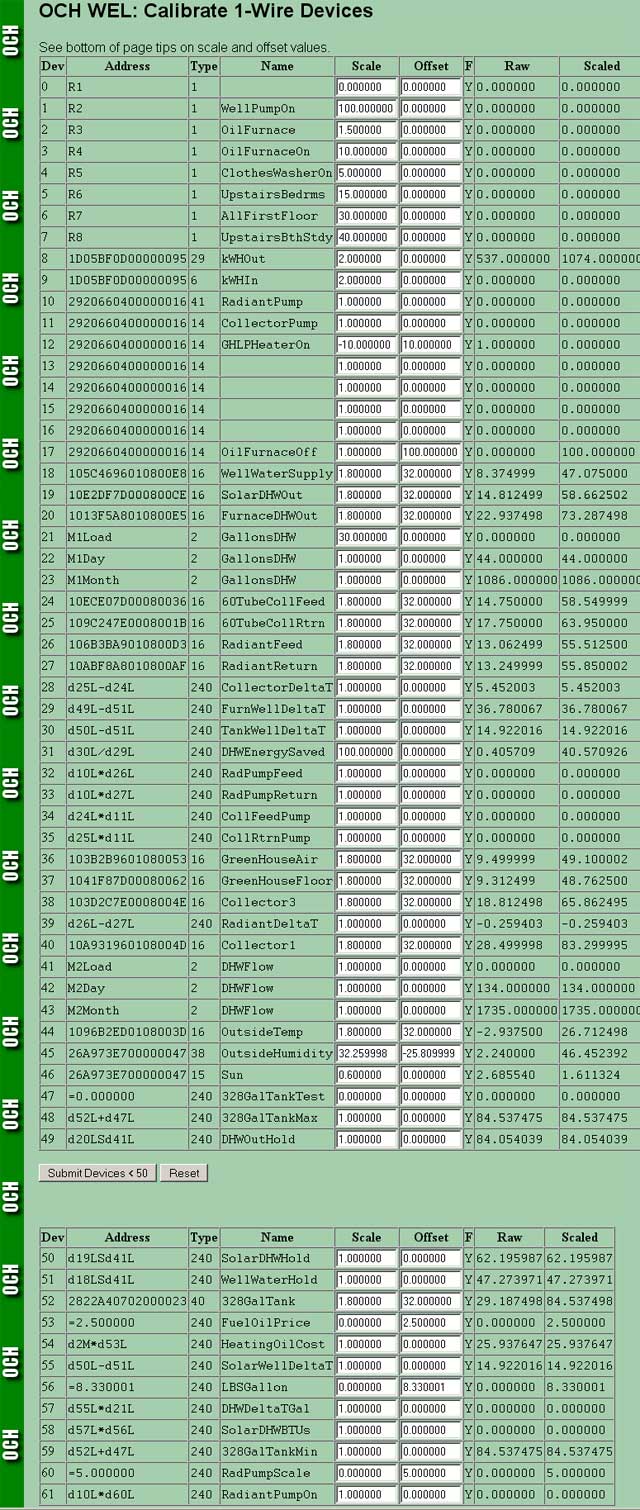

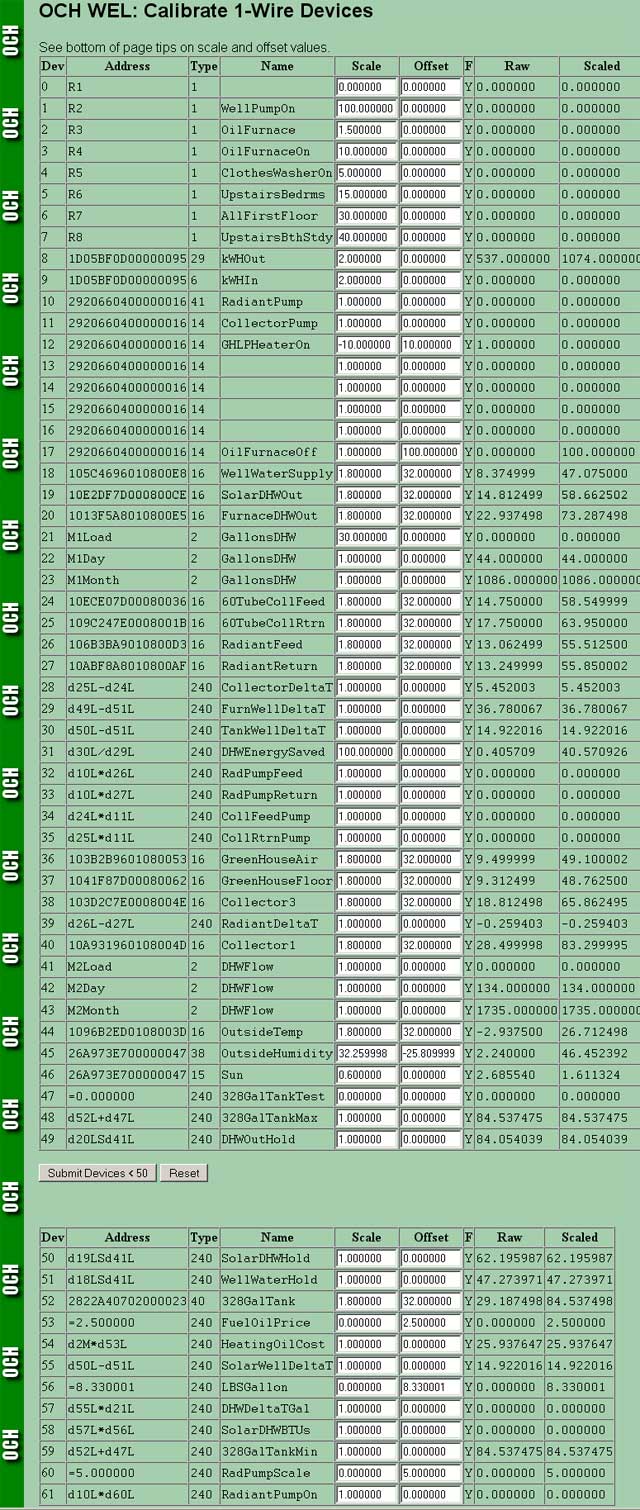

WEL Calibration Table

"WellPumpOn" scale is 100 so that it will show up on the graph with values from 0-2,400.

"OilFurnace" scale is 1.5 because the furnace uses 1.5gal/hr of fuel oil.

"OilFurnaceOn" is jumpered from OilFurnace so I can also have a value large enough to show up on a graph with values from 0-160. The same is true for devices 4-7.

kWH scale is 2 because of the way pulses are counted.

Devices 10 and 11 are scaled to 1 as an "on" state.

GHLPHeater (greenhouse LP heater) is scaled negative (-) because the "off" state of the thermostat shows voltage. I used negative -10 so the value would show up on a graph with values from 0-160.

"OilFurnaceOff" is a virtual device I created so that when I turn the furnace off "The Present Hot Water Supply" would show 100% solar.

Temperature sensors are scaled to 1.8 and offset to 32 to convert the native sensor output of Celsius to Fahrenheit.

"GallonsDHW" is scaled to 30 because the flow meter counts once per gallon to the pulse input that accumulates 1/60 an hour. Confusing right? That's why I'm putting this on my website.

"DHWEnergySaved" scale is 100 to convert a decimal to a whole number percentage.

"Sun" sensor puts out volts, which I calibrated, with trial and error, to .6 for values of 0-100 percent.

"DHWOutHold" samples "DHWOut" temperatures as long as "DHWFlow" has a value of 1 (flow detected). Once the "DHWFlow" goes to 0 (no flow), the last temperature value is held. This prevents values from dropping to ambient, which would throw off BTU calculations. You want to calculate BTU's using temperatures only when hot water is actually being used.

Our flow detector will work to flow rates as low as 1/16th of a gallon per minute. Low flow detection is necessary because of mixing hot and cold water at the faucet, which can make hot water flow rates very low. Because we could not find a flow detector to meet our specifications, we designed and built our own.

|