|

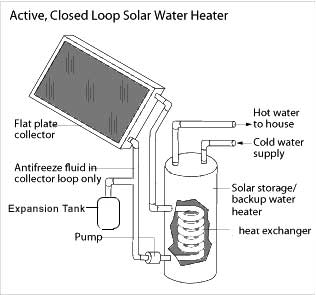

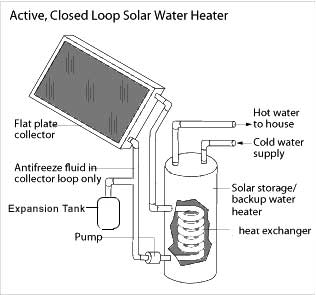

Active Closed Loop - Glycol System

Closed loop systems use a heat-transfer fluid to collect heat and a heat exchanger to transfer the heat to household water. Active closed loop systems use electric pumps, valves, and controllers to circulate the heat-transfer fluid, usually a polypropylene (non toxic, unlike polyethylene) glycol-water antifreeze mixture, through the collectors. This glycol-water antifreeze mixture makes closed-loop glycol systems effective in areas subject to freezing weather. Click HERE to learn how to recharge a closed loop system.

Advantages

1)Closed Loop systems can be utilized in regions that experience temperatures below freezing. Pipes can burst when water freezes. This is prevented by using a fluid (polypropylene glycol) that has a much lower freezing point than water.

2)It is also possible to use low power, photovotaic (PV) pumps. Once the system is charged (using a drill pump) there is no need to overcome gravity, so a low powered pump works fine.

3)Not only can this type of system be completely powered by the sun, but a PV pump runs at a variable speed, making the system run as efficiently as possible. Click HERE to see how we designed our system.

Disadvantages

1)Closed Loop systems require the use of a heat exchanger. This adds some inefficiencies to the system that must be taken into consideration during the design and system sizing stage.

2)You also need a way to control excess heat in the storage tank, usually a radiator acting as a heat dump. You can also tilt the collectors to the winter sun angle (your latitude plus 22.5 degrees) to minimize heat dump requirements.

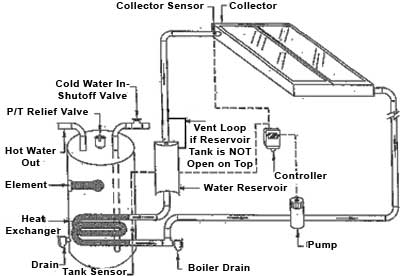

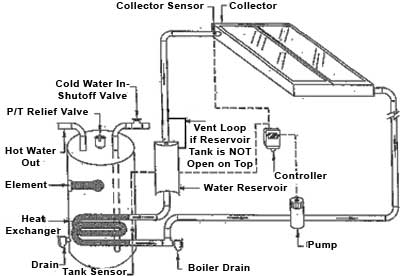

Closed Loop - Drainback System with Heat Exchanger

Drainback systems use water as the heat-transfer fluid within the collector loop. The water is forced through the collectors by a pump and then is drained by gravity to the storage tank and heat exchanger. These systems have no valves to fail and when the pumps are off, the collectors are empty, thereby assuring freeze-protection and auto shut-off if the water in the storage tank becomes too hot.

Advantages

1)The biggest advantage of a drainback system is the high limit feature of differential controllers that

turns the pump off, allowing water to drain out of the collectors to the reservoir protecting the collectors from overheating. The system is immune

to utility blackouts because the water drains back to the reservoir when there is no electricity to run the pump.

2) Since water is used as a heat transfer fluid, it never needs to be changed like pressurized

antifreeze systems. Most plumbing

codes do not require double wall heat exchangers for drainback systems with distilled water.

3) The system has no check valves, no airvents, no pressure gauges,

and no expansion tanks.

4) Cannot reverse thermosyphon at night.

5) Drainback systems may out-heat antifreeze systems by up to 7%.

Drainback Requirements, and Disadvantages

1)THE SYSTEM'S COLLECTOR(S) AND ALL PIPING MUST BE ABOVE AND SLOPE DOWNWARDS (AT LEAST 1/4 INCH PER FOOT) TOWARDS THE RESERVOIR AND

THE HEAT EXCHANGE TANK IN ORDER TO DRAINBACK.

2) They use more energy than a closed loop system because they must pump water against gravity to reach the collector height.

3) As with Active Closed Loop Systems, Drainback Systems can use a heat exchanger. This adds some inefficiencies to the system that must be taken into consideration during the design and system sizing stage.

4) Larger piping (3/4" copper pipe) and insulation must be used.

5) High head AC pumps are most often used with

drainback systems. The pumps require 140 watts for the TACO 009 BF and 205 watts for the

Grundfos UP26-96 BF. These pumps have enough head and flow rate for four (4 x10)'s or five (4x8)'s with a total pipe run of less than 120 ft. The power requirements are about a 10% reduction of savings from the system for the parasitic power loss of running the pump Aand the differential control.

The TACO 009 is preferable due

to the lower power consumption. You may have to put two pumps in series if the static lift to the collector is over 30 feet above the reservoir water level. The second pump can turn off after start up.

Note: You can substitute the lower power (85 watts) Taco 008 or Grundfos UP15-42 Series pumps

for the Taco 009 or the Grundfos UP26-96 Series pumps IF the top of the collectors are less than fifteen feet above the bottom of the reservoir.

6) The drainback system components cost about 10-15% more than a glycol system on a residential

water heating system.

7) Drainback systems can be noisy - like a coffee percolator. Make sure the water returns at

a right angle or two above the water reservoir to cut back the noise of falling water. Adding a water

heater insulation jacket to the reservoir can help minimize noise and reduce heat loss from the reservoir.

8) A 20 gallon hot water tank used as a reservoir will typically require a shelf that can hold at least 200 pounds.

|